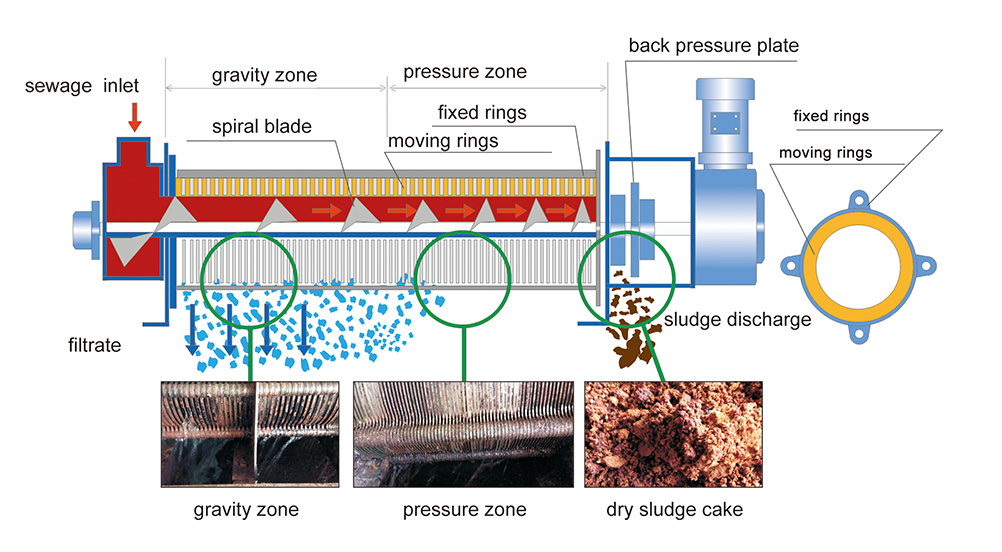

Ish printsipi:

Konditsioner loy flokulyatsiya tankidan suvsizlanish zonasiga beriladi. Vintli mil va harakatlanuvchi halqalardan hosil bo'lgan toraytiruvchi bo'shliqlar orqali o'tayotganda bosim kuchayadi va suv asta-sekin siqib chiqariladi.

Ajratilgan suv harakatlanuvchi va qo'zg'almas halqalar orasidagi bo'shliqlardan oqib o'tadi, ular halqalarning o'zlari harakati bilan avtomatik ravishda tozalanadi - tiqilib qolishning oldini oladi va uzluksiz ishlashni ta'minlaydi. Siqilgan loy keki nihoyat oxiridan chiqariladi.

Asosiy xususiyatlar:

Past konsentratsiyali loy uchun oldindan kontsentratsiya

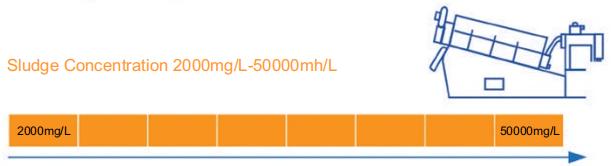

Eksklyuziv spiral plastinka bilan jihozlangan mashina oldindan konsentratsiyani samarali amalga oshiradi, bu esa uni past konsentratsiyali loyni tozalash uchun ayniqsa mos keladi. An'anaviy gravitatsiyaviy dehidratorlarni almashtirish va flokulyatsiya va kontsentratsiya jarayonlarini birlashtirish orqali loyni tozalashni soddalashtiradi. Solenoid nazorat valfi suvsizlanish samaradorligini oshirish uchun atala konsentratsiyasini yanada oshiradi.

1. O'z-o'zini tozalash halqalari bilan tiqinsiz dizayn

HLDS filtr matolari o'rniga harakatlanuvchi va mahkamlangan halqalardan foydalanadi, bu tiqilib qolish muammolarini bartaraf qiladi va texnik xizmat ko'rsatish ehtiyojlarini kamaytiradi. Ayniqsa, yog'li va past konsentratsiyali loy uchun javob beradi va yuqori bosimli tozalashni talab qilmaydi, ikkilamchi ifloslanishni kamaytiradi.

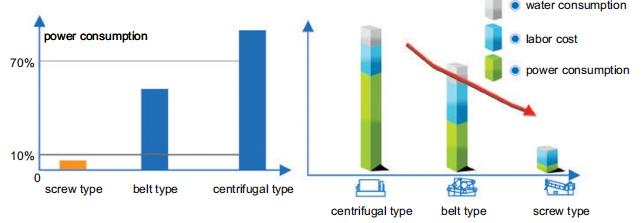

2. Past tezlikda, energiya tejamkor ishlash

Tasmali yoki markazdan qochma tizimlarga qaraganda ancha past aylanish tezligi bilan HLDS vintli pressi tarmoqli presslarga nisbatan energiya sarfini 87,5% gacha va santrifüjlarga nisbatan 95% ga kamaytiradi. Bundan tashqari, ish paytida kamroq shovqin hosil qiladi.

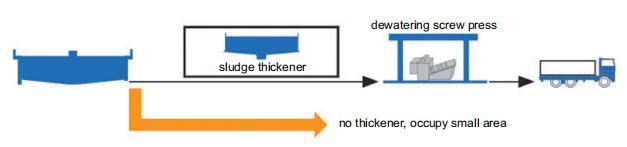

3. Kamaytirilgan infratuzilma va operatsion xarajatlar

Vintli loyni suvsizlantirish mashinasi loyni to'g'ridan-to'g'ri aeratsiya va cho'kindi tanklaridan tozalashi mumkin, bu esa quyuqlashtiruvchi tanklarga bo'lgan ehtiyojni yo'q qiladi va fosforning chiqishini kamaytiradi. U kamroq maydonni talab qiladi, bu esa oqava suvlarni tozalash inshootlariga kapital qo'yilmalarning kamayishiga olib keladi.

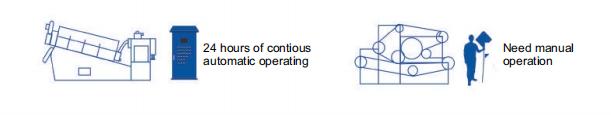

4. Avtomatlashtirilgan boshqaruv va oddiy operatsiya

PLC asosidagi elektr boshqaruv kabinasi bilan birlashtirilgan tizim to'liq avtomatlashtirilgan ishlashni qo'llab-quvvatlaydi. Tiqilib qoladigan komponentlarning yo'qligi barqaror, kam texnik xizmat ko'rsatishni ta'minlaydi - 24/7 qarovsiz ishlashni talab qiluvchi ob'ektlar uchun ideal.

Ilovalar:

Suvsizlantiruvchi vintli press juda ko'p qirrali va loy turlari va sanoatning keng doirasi uchun qo'llaniladi:

- ✅ Shahar oqava suvlarini tozalash

- ✅ Neft-kimyo va kimyo sanoati

- ✅ Sellyuloza va qog'oz tegirmonlari

- ✅ Farmatsevtika va bo'yash zavodlari

- ✅ Go'sht va sut mahsulotlarini qayta ishlash

- ✅ Kon chiqindi suvlari

- ✅ Poligrafiya va bo'yash sanoati

- ✅ Septik idishdagi loy

- ✅ Palma yog'i va sut fermalari chiqindilari

Siz faollashtirilgan loyni, DAF loyini, aralash loyni yoki kimyoviy cho'kmalarni boshqarasizmi, bu vint press suvsizlantirish mashinasi yuqori samaradorlikni va investitsiya daromadini ta'minlaydi.

Texnik parametrlar:

| Turi | Xom chiqindi suv / chiqindi faol loy / kimyoviy cho'kma loy | Eritilgan havo loylari | Aralashtirilgan xom loy | ||

| Loy konsentratsiyasi (TS) | 0,20% | 1,00% | 2,00% | 5,00% | 3,00% |

| HLDS-131 | ~4kg-DS/soat(~2,0m³/soat) | ~6kg-DS/soat(~0,6m³/soat) | ~10kg-DS/soat (~0,5m³/soat) | ~20kg-DS/soat (~0,4m³/soat) | ~26kg-DS/soat(~0,87m³/soat) |

| HLDS-132 | ~8kg-DS/soat(~4,0m³/soat) | ~12kg-DS/soat(~1,2m³/soat) | ~20kg-DS/soat (~1,0m³/soat) | ~40kg-DS/soat (~0,5m³/soat) | ~52kg-DS/soat(~1,73m³/soat) |

| HLDS-133 | ~12kg-DS/soat (~6,0m³/soat) | ~18kg-DS/soat(~1,8m³/soat) | ~30kg-DS/soat (~1,5m³/soat) | ~60kg-DS/soat (~1,2m³/soat) | ~72kg-DS/soat(~2,61m³/soat) |

| HLDS-201 | ~8kg-DS/soat(~4,0m³/soat) | ~12kg-DS/soat(~1,2m³/soat) | ~20kg-DS/soat (~1,0m³/soat) | ~40kg-DS/soat (~0,8m³/soat) | ~52kg-DS/soat(~1,73m³/soat) |

| HLDS-202 | ~16kg-DS/soat (~8,0m³/soat) | ~24kg-DS/soat(~2,4m³/soat) | ~40kg-DS/soat(~2,0m³/soat) | ~80kg-DS/soat (~1,6m³/soat) | ~104kg-DS/soat(~3,47m³/soat) |

| HLDS-203 | ~24kg-DS/soat (~12,0m³/soat) | ~36kg-DS/soat (~3,6m³/soat) | ~60kg-DS/soat (~3,0m³/soat) | ~120kg-DS/soat (~2,4m³/soat) | ~156kg-DS/soat (~5,20m³/soat) |

| HLDS-301 | ~20kg-DS/soat (~10,0m³/soat) | ~30kg-DS/soat (~3,0m³/soat) | ~50kg-DS/soat (~2,5m³/soat) | ~100kg-DS/soat (~2,0m³/soat) | ~130kg-DS/soat (~4,33m³/soat) |

| HLDS-302 | ~40kg-DS/soat (~20,0m³/soat) | ~60kg-DS/soat (~6,0m³/soat) | ~100kg-DS/soat (~5,0m³/soat) | ~200kg-DS/soat (~4,0m³/soat) | ~260kg-DS/soat (~8,67m³/soat) |

| HLDS-303 | ~60kg-DS/soat (~30,0m³/soat) | ~90kg-DS/soat (~9,0m³/soat) | ~150kg-DS/soat (~7,5m³/soat) | ~300kg-DS/soat (~6,0m³/soat) | ~390kg-DS/soat (~13,0m³/soat) |

| HLDS-304 | ~80kg-DS/soat (~40,0m³/soat) | ~120kg-DS/soat (~12,0m³/soat) | ~200kg-DS/soat (~10,0m³/soat) | ~400kg-DS/soat (~8,0m³/soat) | ~520kg-DS/soat (~17,3m³/soat) |

| HLDS-351 | ~40kg-DS/soat (~20,0m³/soat) | ~60kg-DS/soat (~6,0m³/soat) | ~100kg-DS/soat (~5,0m³/soat) | ~200kg-DS/soat (~4,0m³/soat) | ~260kg-DS/soat (~8,67m³/soat) |

| HLDS-352 | ~80kg-DS/soat (~40,0m³/soat) | ~120kg-DS/soat (~12,0m³/soat) | ~200kg-DS/soat (~10,0m³/soat) | ~400kg-DS/soat (~8,0m³/soat) | ~520kg-DS/soat (~17,3m³/soat) |

| HLDS-353 | ~120kg-DS/soat (~60,0m³/soat) | ~180kg-DS/soat (~18,0m³/soat) | ~300kg-DS/soat (~15,0m³/soat) | ~600kg-DS/soat (~12,0m³/soat) | ~780kg-DS/soat (~26,0m³/soat) |

| HLDS-354 | ~160kg-DS/soat (~80,0m³/soat) | ~240kg-DS/soat (~24,0m³/soat) | ~400kg-DS/soat (~20,0m³/soat) | ~800kg-DS/soat (~16,0m³/soat) | ~1040kg-DS/soat (~34,68m³/soat) |

| HLDS-401 | ~70kg-DS/soat(~35,0m³/soat) | ~100kg-DS/soat (~10m³/soat) | ~170kg-DS/soat (~8,5m³/soat) | ~340kg-DS/soat (~6,5m³/soat) | ~442kg-DS/soat(~16,0m³/soat) |

| HLDS-402 | ~135kg-DS/soat (~67,5m³/soat) | ~200kg-DS/soat (~20,0m³/soat) | ~340kg-DS/soat (~17,0m³/soat) | ~680kg-DS/soat (~13,6m³/soat) | ~884kg-DS/soat(~29,5m³/soat) |

| HLDS-403 | ~200kg-DS/soat (~100m³/soat) | ~300kg-DS/soat (~30,0m³/soat) | ~510kg-DS/soat (~25,5m³/soat) | ~1020kg-DS/soat (~20,4m³/soat) | ~1326kg-DS/soat (~44,2m³/soat) |

| HLDS-404 | ~266kg-DS/soat (~133m³/soat) | ~400kg-DS/soat (~40,0m³/soat) | ~680kg-DS/soat (~34,0m³/soat) | ~1360kg-DS/soat (~27,2m³/soat) | ~1768kg-DS/soat (~58,9m³/soat) |

| Turi | Chiqarish balandligi | O'lchamlari | Og'irligi (kg) | Quvvat (kVt) | Yuvish suvi (L/soat) | |||

| L(mm) | Vt(mm) | H(mm) | Bo'sh | Ishlayotgan | ||||

| HLDS-131 | 250 | 1860 | 750 | 1080 | 180 | 300 | 0.2 | 24 |

| HLDS-132 | 250 | 1960 yil | 870 | 1080 | 250 | 425 | 0,3 | 48 |

| HLDS-133 | 250 | 1960 yil | 920 | 1080 | 330 | 580 | 0.4 | 72 |

| HLDS-201 | 350 | 2510 | 900 | 1300 | 320 | 470 | 1.1 | 32 |

| HLDS-202 | 350 | 2560 | 1050 | 1300 | 470 | 730 | 1.65 | 64 |

| HLDS-203 | 350 | 2610 | 1285 | 1300 | 650 | 1100 | 2.2 | 96 |

| HLDS-301 | 495 | 3330 | 1005 | 1760 | 850 | 1320 | 1.3 | 40 |

| HLDS-302 | 495 | 3530 | 1290 | 1760 | 1300 | 2130 | 2.05 | 80 |

| HLDS-303 | 495 | 3680 | 1620 | 1760 | 1750 | 2880 | 2.8 | 120 |

| HLDS-304 | 495 | 3830 | 2010 yil | 1760 | 2300 | 3850 | 3.55 | 160 |

| HLDS-351 | 585 | 4005 | 1100 | 2130 | 1100 | 1900 | 1.3 | 72 |

| HLDS-352 | 585 | 4390 | 1650 | 2130 | 1900 | 3200 | 2.05 | 144 |

| HLDS-353 | 585 | 4520 | 1980 yil | 2130 | 2550 | 4600 | 2.8 | 216 |

| HLDS-354 | 585 | 4750 | 2715 | 2130 | 3200 | 6100 | 3.55 | 288 |

| HLDS-401 | 759 | 4680 | 1110 | 2100 | 1600 | 3400 | 1.65 | 80 |

| HLDS-402 | 759 | 4960 | 1760 | 2100 | 2450 | 5200 | 2.75 | 160 |

| HLDS-403 | 759 | 5010 | 2585 | 2100 | 3350 | 7050 | 3.85 | 240 |

| HLDS-404 | 759 | 5160 | 3160 | 2100 | 4350 | 9660 | 4.95 | 320 |

-

Septik tanklar va chiqindilar uchun deodorizatsiya agenti...

-

Chuqur plastinka bilan samarali loyni suvsizlantirish...

-

Chiqindilarni tozalash uchun nitrifikatsion bakteriyalar agenti

-

Oqava suvlarni qattiq suyuqlikdan ajratish uchun statik ekran...

-

Halotolerant bakteriyalar - Advanced Bioremed...

-

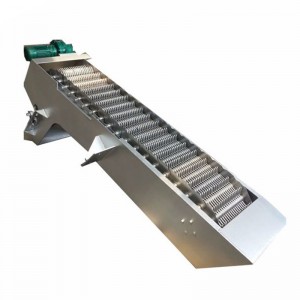

Chiqindilarni oldindan tozalash uchun mexanik bar ekrani ...